Stainless Steel Filling Station with 300 GPD Reverse Osmosis System

The Reverse Osmosis (RO) system is one of the most complete under the counter systems available. It has the ability to eliminate up to 99.8% of harmful contaminants in water such as bacteria, viruses, lead, radium, chlorine, and arsenic. It makes use of multi-stage filtration technology.

With the RO system, you can rest assured that your drinking water is clean, clear and healthy.

The 300 GPD Reverse Osmosis system will produce 30 to 60 Litres of water Per Hour.

The Stainless Steel Filling Station (sometimes referred to as a Water Bar) allows you to easily fill client's bottles or containers with the filtered water.

**IMPORTANT** Please Note the Following:

- This Stainless Steel Filling Station setup is meant for filling client's Bottles and Containers ONLY. This setup is not designed to be used for Bottling, as it will not give the bottles a shelf life.

- The Stainless Steel Filling Station and 300GPD RO System are only meant for municipal source waters. If you are using an alternative source water (such as borehole, river, dams, etc), then we will require a full water test result (analysis), in order to give you a quotation for a system to meet your source water's needs.

- The Stainless Steel Filling Station's price does not include shipping charges. Please note that due to the glass component, and size of the unit, the Stainless Steel Filling Station cannot be shipped with our regular couriers and is available for in-store collection (in Centurion, Pretoria) only. Lead Time is 3 to 5 working days, from when payment is received.

- The Stainless Steel Filling Station's price does not include installation charges. Filtershop does not have in-house installers however, the Stainless Steel Filling Station can be installed by a normal plumber.

The Stainless Steel Filling Station also creates a nice display piece for your store, with the glass tank section which has bubbles and lighting.

The Stainless Steel Filling Station also has a basin for filling, with a built-in drain for spilled water.

The Stainless Steel Filling Station with the 300 GPD RO System includes the following:

- 300 GPD Reverse Osmosis System

- Stainless Steel Filling Station

- Lighting

- Bubbler

The 300 GPD Reverse Osmosis system has 4 stages:

- Stage 1: 10 Inch Sediment Filter (5 Micron) - Removes Particles, Dirt, Sand, Mud, Rust, and other large visible particles in the water. At 1 Micron You also start to capture some bacteria from the water.

- Stage 2: 10 Inch Granular Activated Carbon (GAC) - Absorbs Chlorine and organic molecules (bad odors) from the water.

- Stage 3: 10 Inch Activated Carbon Block - Further reduce the chlorine and organic molecules. The Carbon Block also has a 5-micron cover to capture any carbon that may drop off during the filtering process.

- Stage 4: Reverse Osmosis Membrane - Removes bacteria, viruses, heavy metals, pesticides, herbicides, and reduces the mineral content (TDS) of water.

- Stage 5: T33 Taste and Odour Filter - Absorbs and organic molecules that may come off of the RO membrane.

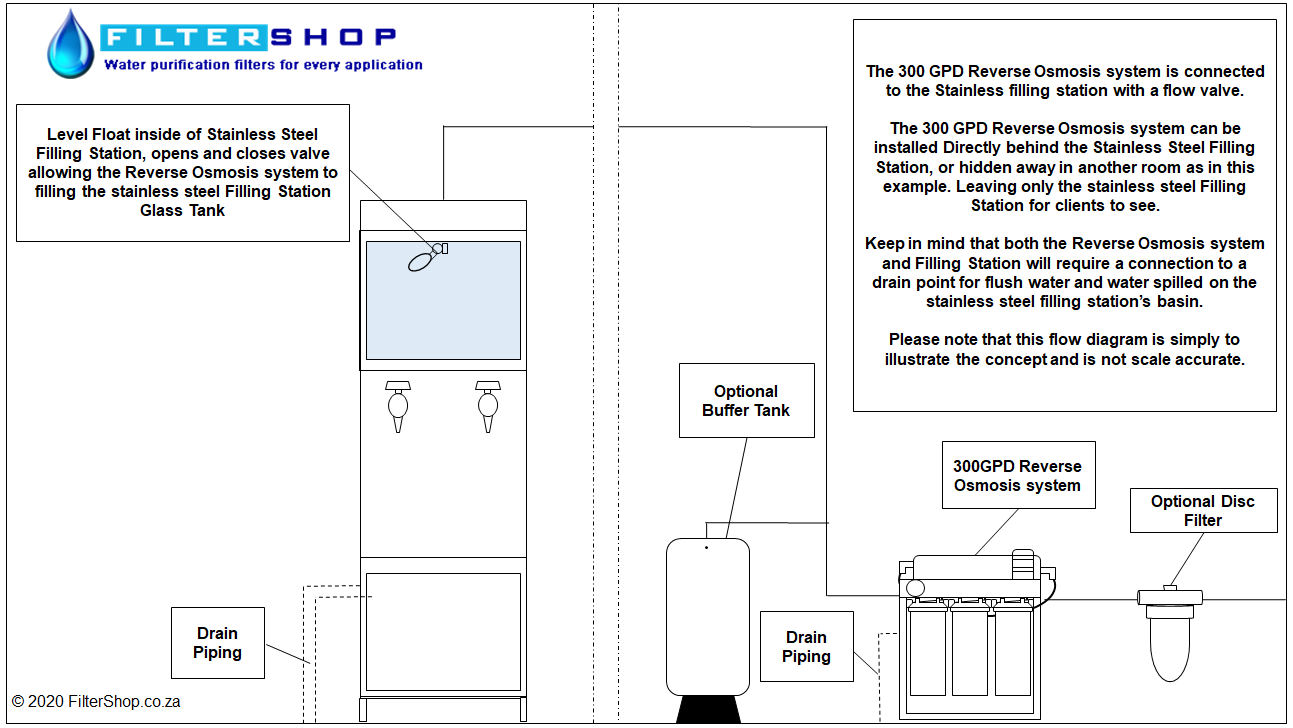

Setup Diagram For Stainless Steel Filling Station

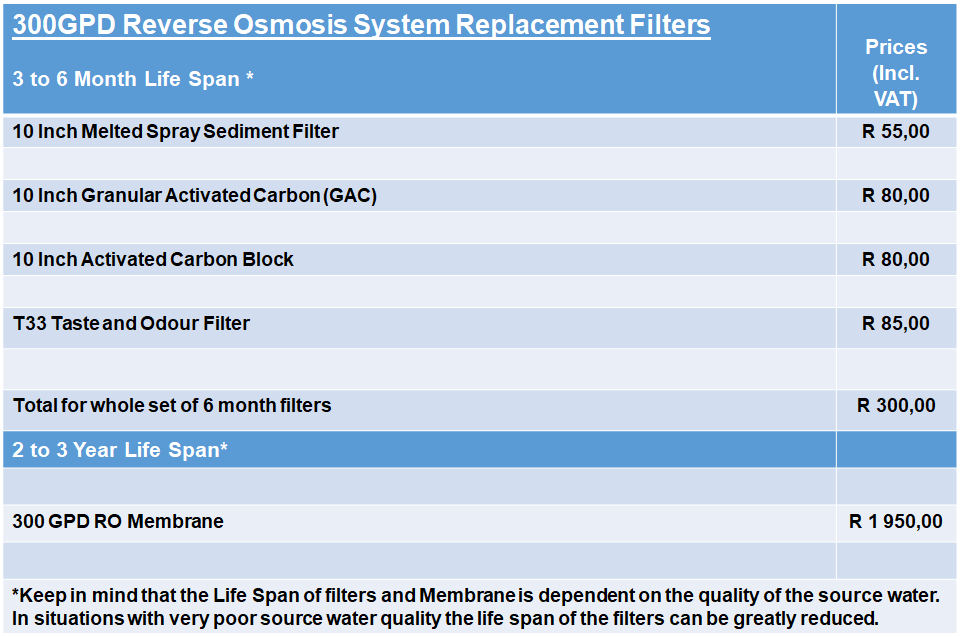

Maintenance Costs:

Keep in mind:

- The system has a water wastage rate of up to 4:1 due to constant flushing of the membrane, so for every 1 Liter of clean, filtered water produced, up to 4 liters will be used to flush the system.

- The Stainless Steel Filling Station basin has a drain, which will require a pipe to a drain point for the spilled water to run off to.

- The production rating of all the RO plants is based on an ideal quality source water, so in situations, with low to poor quality source water, the actual flow rate produced by an RO plant can be as low as 30 to 70 % of the actual rated capacity. So in the case of the 400 GPD RO System, you are like to find you get 20 to 50 Litres Per Hour Production.

- As stated previously the Filling Station itself is not designed for bottling. Bottling requires that the bottles are given a shelf life, by dosing Ozone into the water prior to filling. In order to dose ozone, you will require an Ozone Generator and a Stainless Steel Storage Tank.

- An important thing to remember before installing any filtration systems is to check what size the source piping is. The standard household piping size is normally 1/2" (12.7mm) or 3/4" (19mm) thick. Some older houses have copper piping sizes instead of a newer system and in such cases, the special attachment will be required to install the RO to the copper piping. In order to ensure that you do not have to buy additional adapters due to the connections not matching the piping, please check what type and size your piping is before ordering a filtration system.

- The Pre-filters and Membrane all have a certain lifespan and must be replaced to ensure that the system works effectively. Failure to do so will affect the quality of the product water as well as the reliability of the system.

Sterilizing Client's Containers and Bottles Prior to Filling

Although the water produced by the filling station will be clean, if the client's container or bottle has bacteria or dirt inside it then it will defeat the whole purpose of the water filtration system.

It is important to rinse and clean the client's container before actually filling it. This can be done using diluting either Milton, or Jik, or Food Grade Hydrogen Peroxide into some water, and using it to clean the container.

Once the bottle has been adequately rinsed and cleaned, then you can fill it with your product water.

What's in the 300 GPD RO's box?

Here are the items and components that are included in the price:

- Mounting bracket and Stand

- 10" Sediment Filter (5 Micron)

- 10" Granular Activated Carbon (GAC/UDF)

- 10" Activated Carbon Block

- T33 Taste and Odor Filter

- Reverse Osmosis membrane (300 Gallon per day)

- 1 Plastic housing spanner (a special tool for replacing the filters)

- 1/4" White tubing and 3/8" White Tubing

- 3 x 10" Filter Housings

- RO Membrane Housing

- Pipe Fittings (Joints, Elbows, T-joints, Non-return valve, valves)

- Flow restrictor

What's included with the Filling Station

- Stainless Steel Filling Table

- Drain for spillage

- Two Filling Valves

- Glass Display Tank

- Bubbler

- Lighting

Not Included in the prices:

- Plumbing and installation costs

- Delivery costs (i.e. Courier / Shipping Charges)

- Replacement Filters

Additional Options:

Additional Storage Tank

The Pressure Storage Tank will create a buffer of pre-filtered water, which will then fill the glass tank on the top of the stainless steel filling station. This has the great benefit of helping to refill the Glass Display take more quickly than it would directly from the Reverse Osmosis system.

There are several sizes of storage tanks available, giving you varying amounts of pre-filtered water.

/Tank Dimensions and Model Numbers.JPG)

Pressure Protection Valve

The Filtration system is rated for a maximum pressure of 6 bar, pressure high than this will damage the system and its components. If you do know that your area or source is prone to high pressure and/or pressure spikes we strongly recommend adding a pressure protection valve between the source water and the filtration system.

Additional Lengths of Piping

The 400 GPD and 800 GPD RO systems use two different sizes of piping.

The source water piping which supplies water from the water source to the Reverse Osmosis system is 3/8" piping.

The piping from the Reverse Osmosis system to the Stainless Steel Filling Station is 1/4".

There are 5 meters of each size piping with the standard system, however additional piping can be ordered if you know either the distance between the source and RO or the RO and the stainless steel filling station will be longer than 5 Metres.

Arkal Disc Filter

In situations where the source water has a large amount of dirt, sand, mud, rust, and other particles present it is a good idea to put a disc filter before the Reverse Osmosis system.

The Disc Filter will capture large dirt, sand, and particles. Which will help to extend the lifespan of the finer 1 Micron Sediment Filter?

The Disc Filter is reusable, and when it becomes block you simply remove it from its housing and wash it.

There are three disc filter sizes available, the main difference between the three is the amount of surface area, the larger the surface area then great the amount of time before the disc filter needs to be cleaned.

The 1 Inch Disc Filter has the smallest surface area, the 1 Inch Super Disc Filter has the second largest, and the 2 Inch Disc Filter has the largest surface area.

The other difference is that the 1 Inch and 1 Inch Super Disc Filter filter down to 55 microns, whereas the 2 Inch Disc Filter filter to a finer 20 Microns.