Ultra Clear Glass Filtration System

The Ultra Clear Glass media is a High-Tech filtration media, used for the removal of sediment, dirt, rust, and other large particles in water. The Ultra Clear Glass Filtration Media is produced from virgin plate-glass.

The Ultra Clear Glass Media can filter down to as fine as +/- 5 Micron, provided the finer grade media is used.

The Ultra Clear Glass Filtration media replaces traditional Silica Sand Media. Filtering to a much finer level, as well as having a much longer life span than typical silica sand media.

The Ultra Clear Glass Filtration Media is available in three grades:

- Ultra Fine (0.425mm to 0.597mm Granules)

- Fine (0.597mm to 1.4mm Granules)

- Coarse (1.4mm to 2mm Granules)

Benefits

- Reduced Backwash time. Water Savings of up to 50%, compared to traditional sand silica media

- Longer Life Span, up to 15 years. Whereas silica sand typically lasts 3 to 5 years.

- Reduced Bacteria growth (Biofilm) through Negative charged surface Area, adding to the increase in Life span.

- Made from 100% Virgin plate-glass.

- Environmentally Friendly, Glass Media is 100% recyclable.

- Filters down to +/- 5 Micron (with Grade 0)

- Particles do not clump together, allowing for easier flow without resistance.

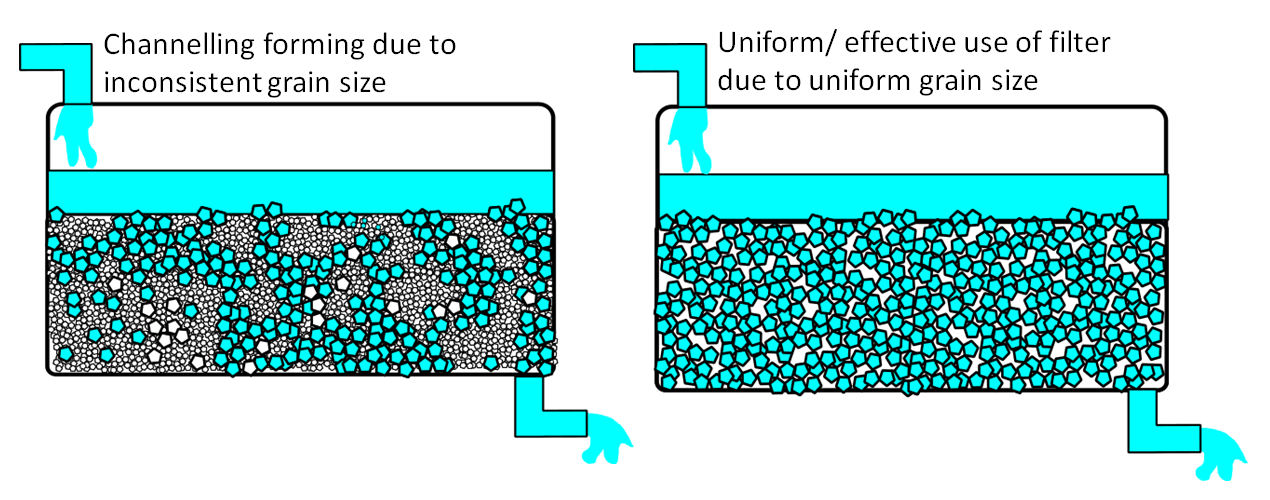

- More uniformed filtration through media, without "channels" forming in the media bed.

Ultra Clear Compared to Traditional Silica Sand

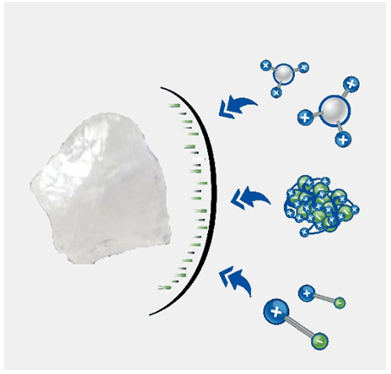

Negative Charged Surface area

Self-sterilizing surface

- When in contact with water flowing through the filter, a small number of free radicals (O- and HO-) are formed on the surface. These free radicals have a very strong oxidation potential which protects the media from bacterial growth

Molecular structure

- Plate glass contains metal oxides which improve the durability, shock resistance and temperature resistance of the product.

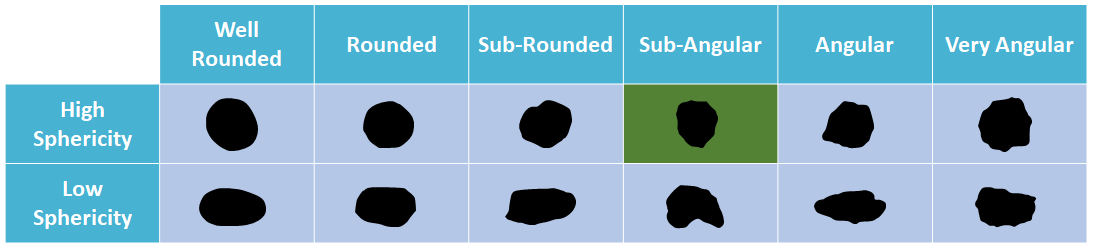

Ultra Clear "Sub-angular" Granule Shape

Particle shape is of extreme importance. Sub-angular particles with high sphericity are needed for the increased contact area. Other crushing methods result in splintered particles that pack tightly against each other and restricts water flow.

Benefits

- Sub-angular Particle Shape Packs Less Dense, preventing resistance and allow for more efficient flow.

- Prevents "channeling" from occurring in the media bed, by having a uniform shape across the Bed Depth.

- Creates an optimum amount of surface area, helping to more effectively remove sediments and particles.

- Is safe to handle (does not cut hands)

Certification

Ultra Clear Glass Media has the following certification:

- ISO 9001:2015

- ISO 14001:2015

- OHSAS 18001:2007

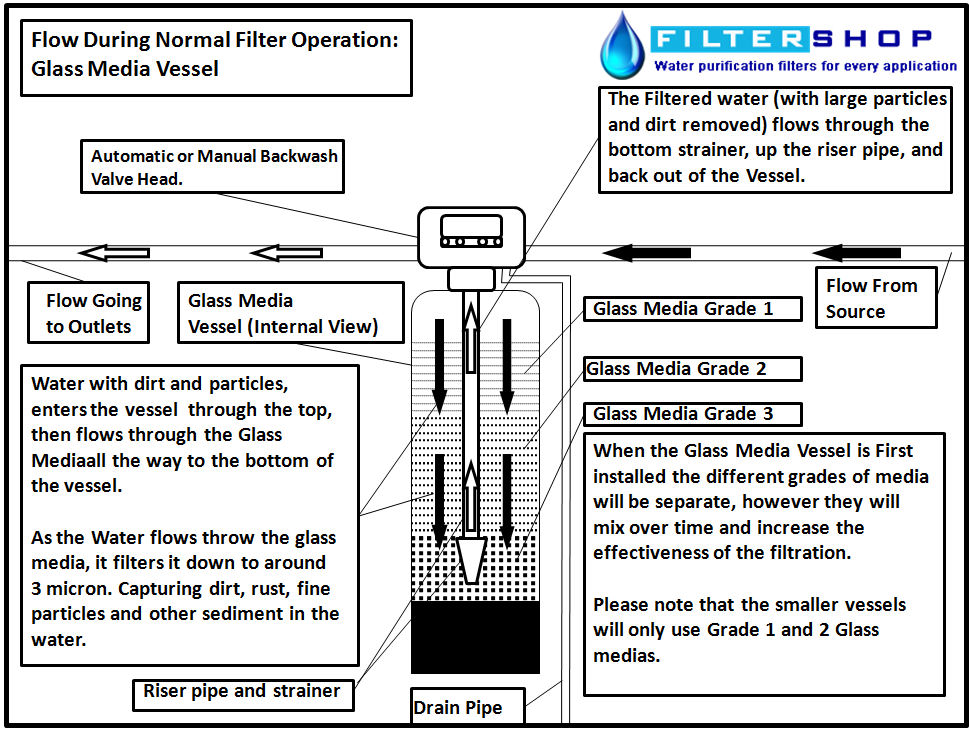

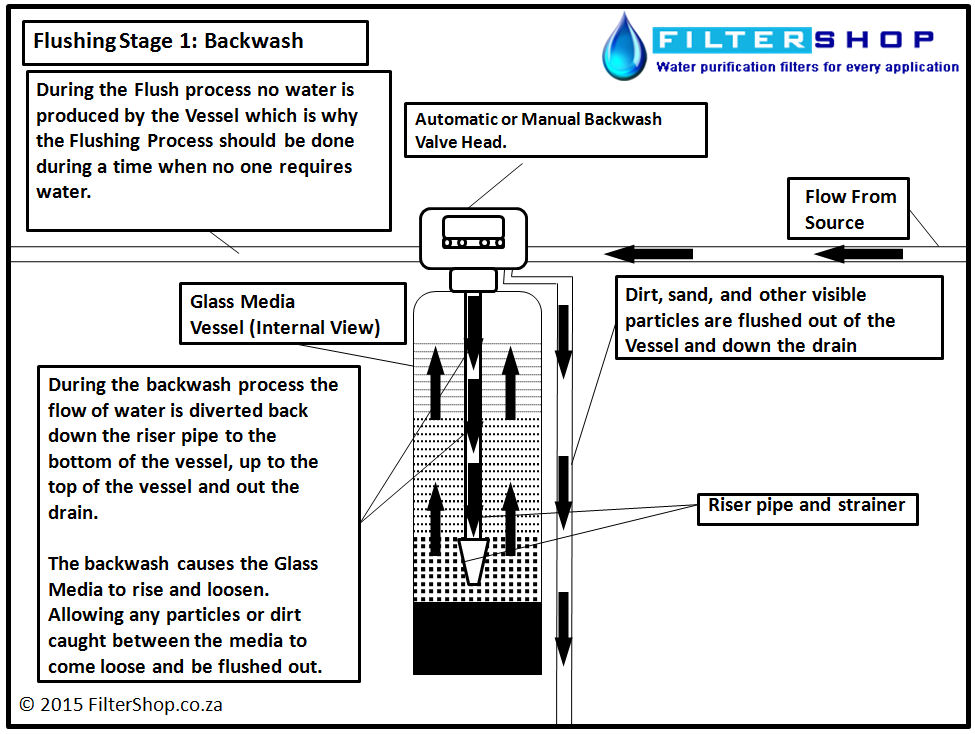

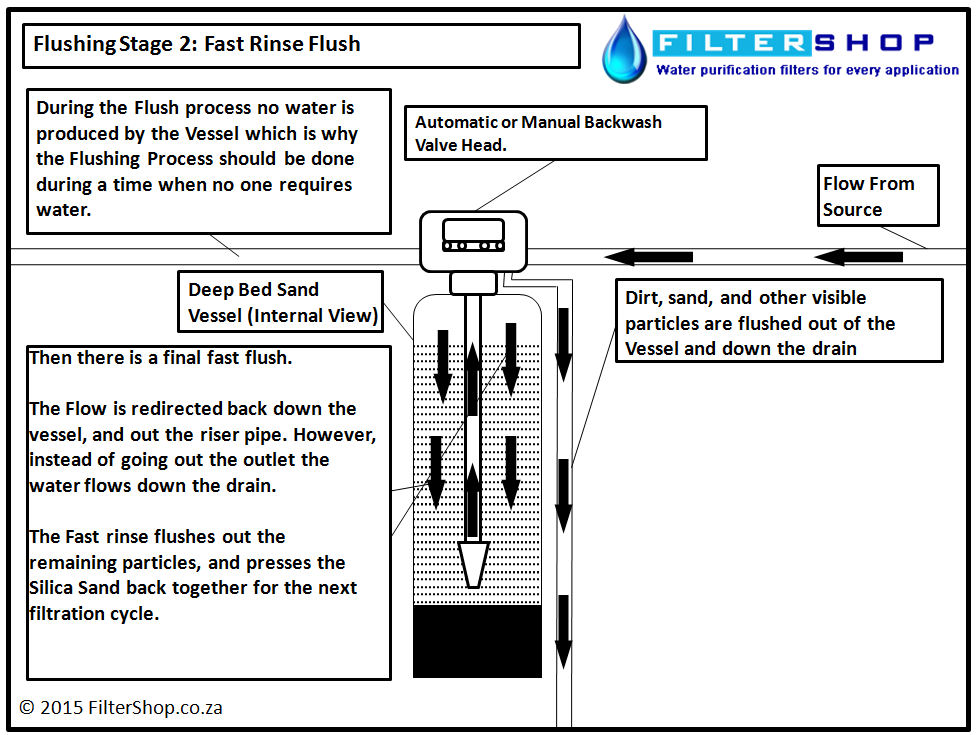

Glass Media Vessel Normal Operation and Backwashing.

During Normal, operation water flows into the top of the vessel and travels all the way to the bottom of the vessel. As the water flows down through the vessel, all the particles, rust, dirt, mud, and other sediment is captured between the glass media granules. The water then enters the bottom strainer, flows up the riser pipe, and out the top of the vessel.

Valve Head Options

Manual Valve Head

- Does not require any power.

- Backwashing must be done manually.

Automatic Valve

- Requires an electrical source to operate (normal 2 pin or 3 pin plug)

- Can be set to automatically backwash the vessel, with either fleck or digital time.

- Please note the Automatic valve will either be a fleck or digital valve, depending on stock availability. A manual for programming the valve head will be provided with the unit.

Additional Options

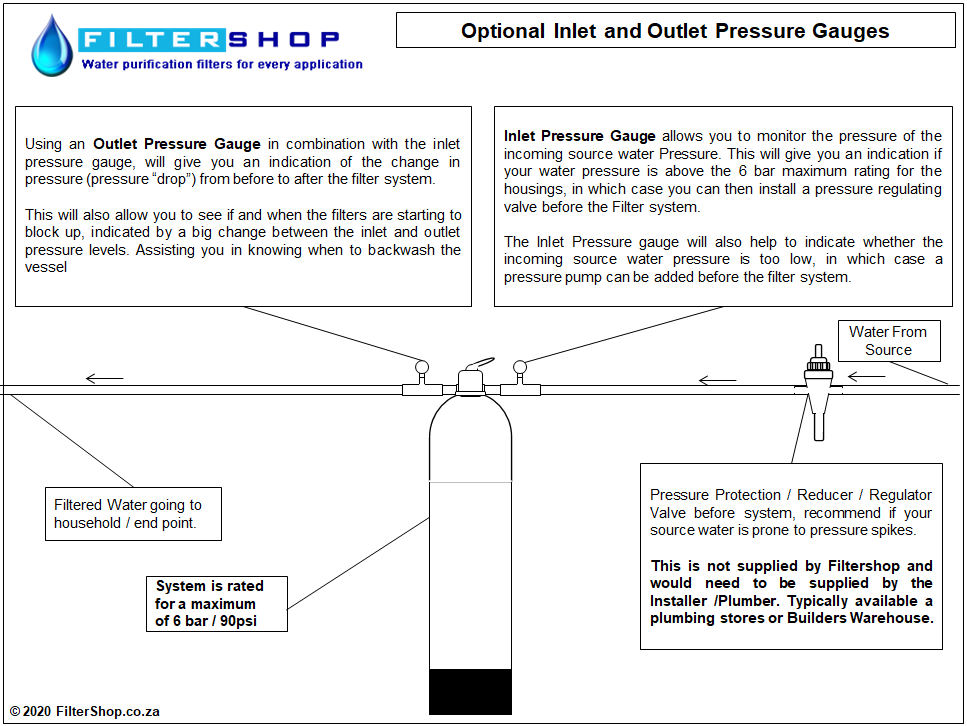

Optional Inlet and Outlet Pressure Gauges

Inlet Pressure Gauge allows you to monitor the pressure of the incoming source water Pressure. This will give you an indication of your water pressure is above the 6 bar maximum rating for the housings, in which case you can then install a pressure regulating valve before the filter system.

The Inlet Pressure gauge will also help to indicate whether the incoming source water pressure is too low, in which case a pressure pump can be added before the filter system.

Using an Outlet Pressure Gauge in combination with the inlet pressure gauge will give you an indication of the change in pressure (pressure “drop”) from before to after the filter system.

This will also allow you to see if and when the filters are starting to block up, indicated by a big change between the inlet and outlet pressure levels. Assisting you in knowing when to replace the filter cartridges inside.

Please note that pressure gauges are built to order, construction time is 2 to 3 working days.

PVC Threaded and Glue Fittings

PVC(Polyvinyl chloride) fittings are used to connect sections of pipes or tubes, adapt to different sizes or shapes, and controlling the flow of water. There are two predominant types of PVC fittings namely PVC Glue Fittings and PVC Threaded Fittings. The difference between the two is that PVC Glue Fittings result in permanent joints and PVC Threaded Fittings are semi-permanent and can be replaced. PVC Glue fittings are joined with primer and cement- a chemical solvent that melts the surface of the PVC and then quickly re-hardens to fuse the pieces together. This results in an airtight, leak-proof bond similar to what you get with welding metal. An example of such a fitting is a PVC Glue Reducing Socket which is used to join together two pieces of PVC pipes with different diameters. Another example would be a 90 Degree Elbow which is used to connect two pipes of the same diameter at an angle of 90 degrees.PVC Threaded fittings utilise a simple threaded connection whereby replaceable 'male threaded' are screwed into 'female threaded'.Male threads have a thread on the outside of the fitting and female threads have a thread on the inside. When you thread the fitting in, it compresses against the other threads.PTFE tape is used to thread these together and the proper way to assemble threaded fittings is to finger tighten, then add one to two turns but no more. An example of a threaded fitting is a Reducing Nipple Male Threaded which is used to connect between two female threads of different diameters.

Link To PVC Fittings